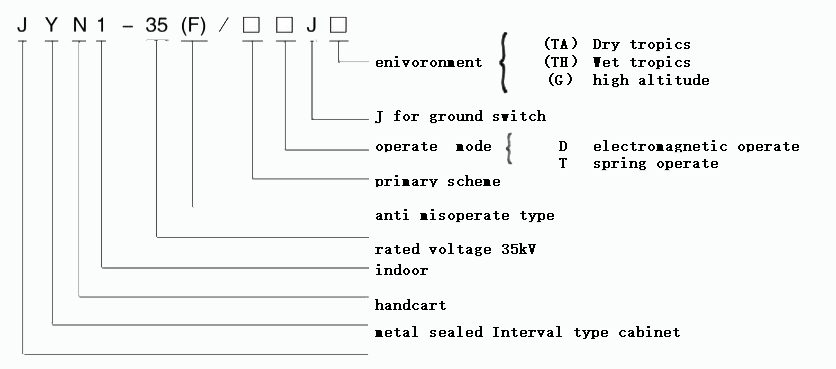

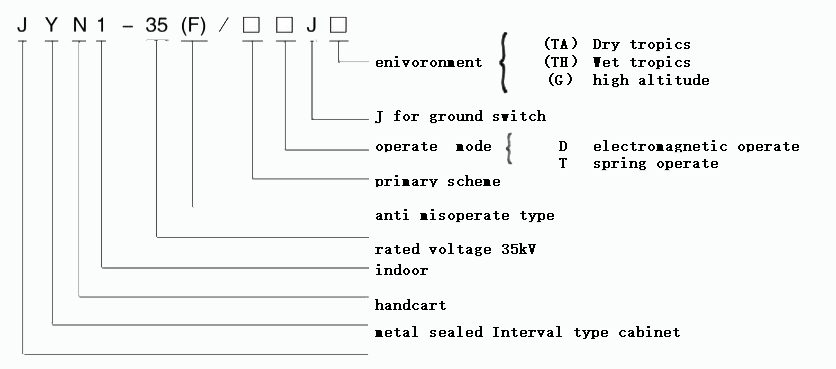

Model No.

Technique data

The primary element assembled on the switch board includes lack oil circuit breaker or vacuum breakerfunction mechanism current mutual inductor ,voltage mutual inductor fuse ,lightning arester ,electric powertransformer and so on ,on the condition that the equipment has ,these elements should have their owntechnique characters.

4.1 Switchboard technique parameter shows on

| code |

Item |

Unit |

data |

| 1 |

rated voltage |

KV |

35 |

| 2 |

max operate voltage |

KV |

40.5 |

| 3 |

max rated current |

A |

1000 |

| 4 |

rated break current |

KA |

16/20/25/31.5 |

| 5 |

rated closing current (peak) |

KA |

40/50/63/80 |

| 6 |

Ultimate breaking and closing current (peak) |

KA |

40/50/63/80 |

| 7 |

4s thermal stable current(effect value) |

KA |

16/20/25/31.5 |

| 8 |

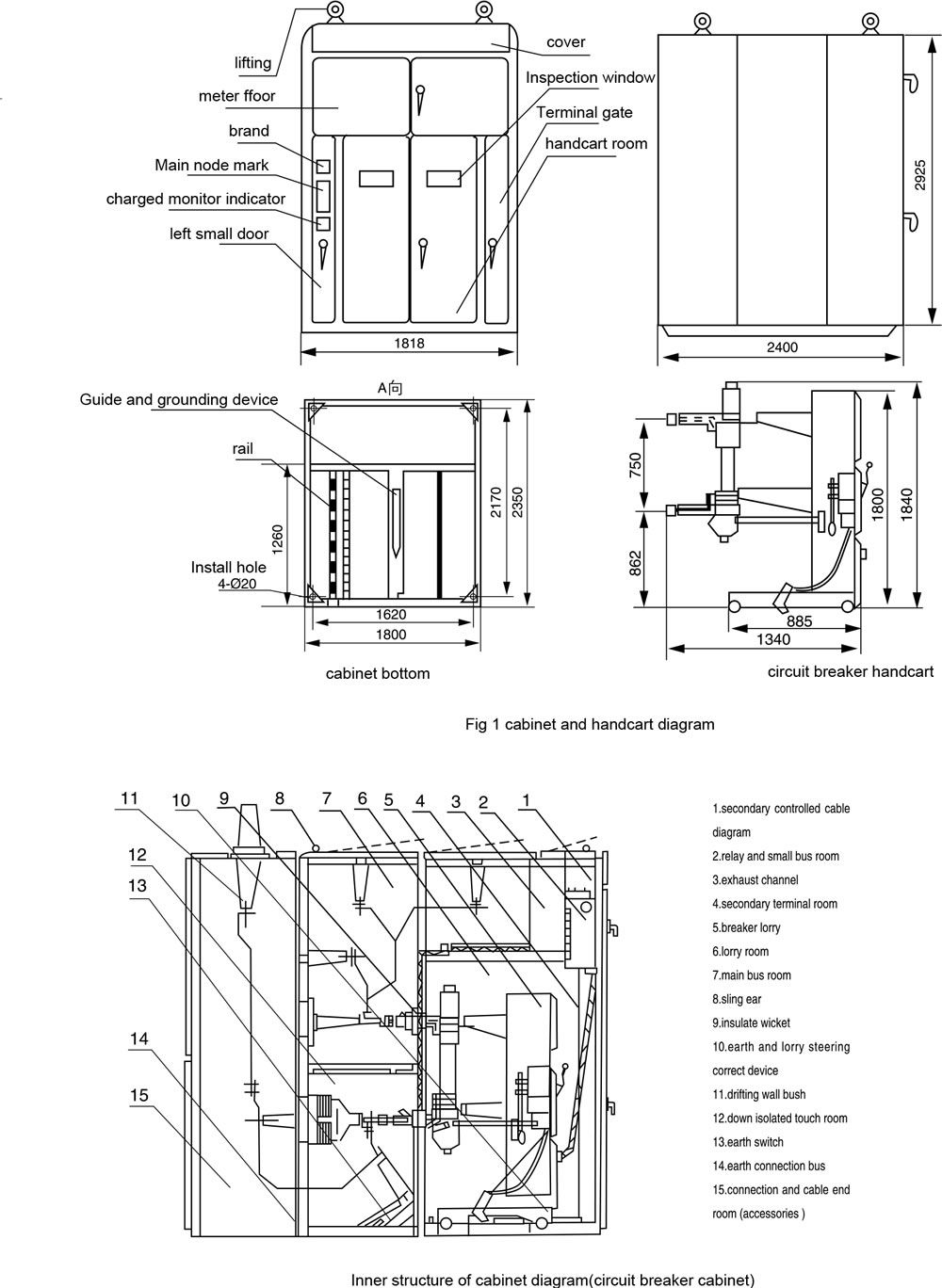

shape(long x width x height) |

KA |

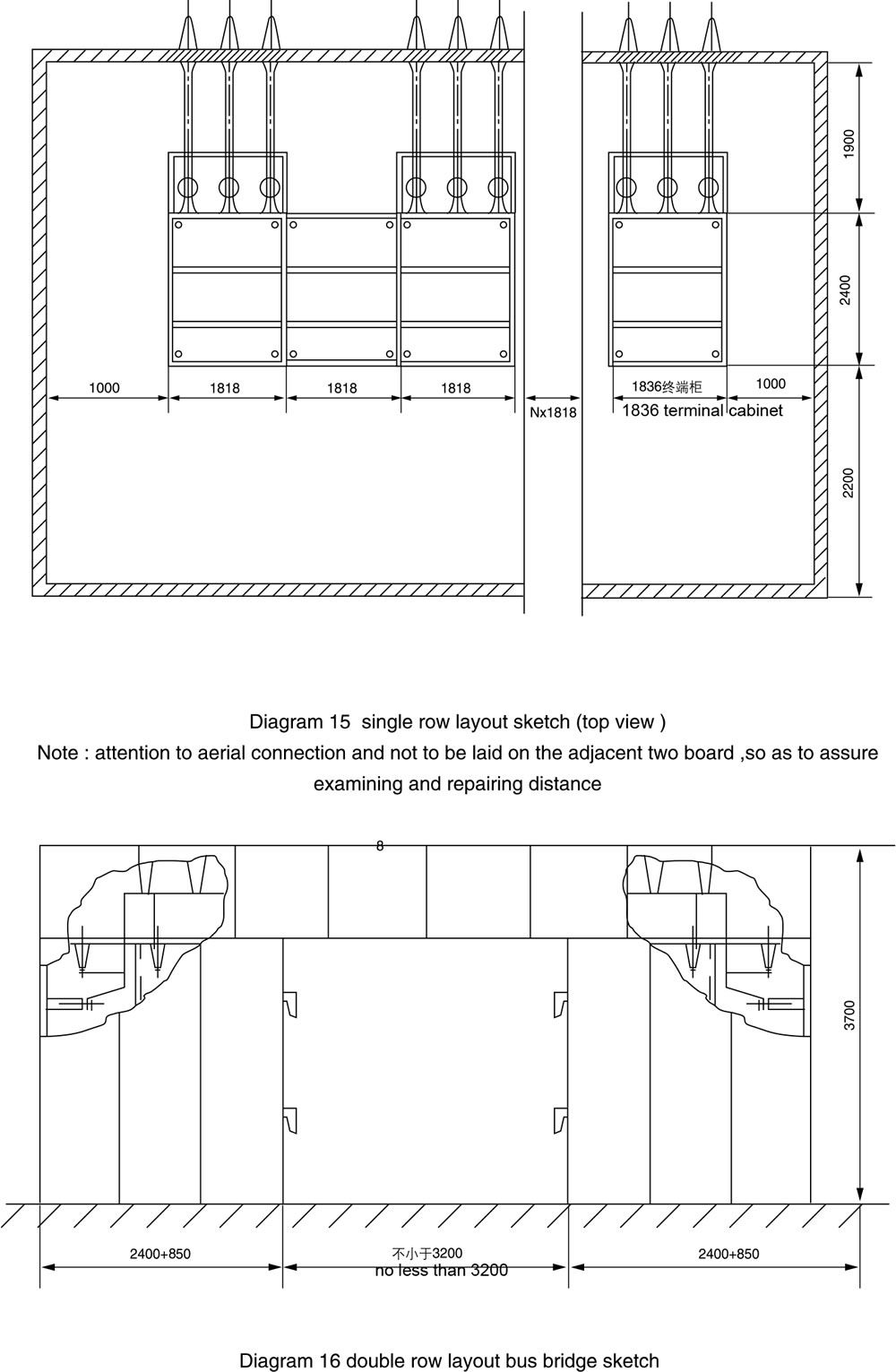

1818(mm)x2400(mm)x2925(mm) |

| 9 |

weight(oil breaker cabinet) |

mm |

1800 (including oil handcart weights 620) |

| 10 |

dyamic loadweight |

Upper |

kg |

about 500 |

| lower |

kg |

about 500 |

| 11 |

Protect level |

kg |

IP2X |

4.2 Lack oil circuit breaker technique data shows on

| code |

Item |

Unit |

data |

| 1 |

rated voltage |

KV |

35 |

| 2 |

Max operate voltage |

KV |

40.5 |

| 3 |

rated current |

KA |

1250 |

| 4 |

rated breaking current |

KA |

16/20 |

| 5 |

rated closing current(peak) |

KA |

20/50 |

| 6 |

ultimate closing and breaking current(peak) |

KA |

20/50 |

| 7 |

4s thermal stable current(effect value) |

KA |

16/20 |

| 8 |

Inherent switching time equip( CD10、CT10 ) |

s |

0.06 |

| 9 |

closing time equip ( CD10、CT10) |

s |

0.25 0.2 |

| 10 |

operate circulation |

breaking – 0.3s – closing and breaking -180s – closing and breaking |

| 4.3 CT10type spring operation mechanism main parameter |

| Stock energy motor type:HDZ1-6. |

| Stock energy motor electric power : not more than 600 w |

| Rated voltage stock energy time under rated voltage does not exceed 8 s . |

| (manipulative matrix does not exceed 7kg .m in the case of stocking energy by hand ). |

| Spring operation mechanism’s unlocking device category : divided activated undocking device |

| (code 4),instantaneously over current undocking(code 1). |

| Instantaneously over current undocking device rated current : 5A |

| Undocking device composition . |

| Please negotiate with manufacture if you need other composition or lose voltage undocking device. |

4.4 Dividable activated undocking device and brake shut electromagnet data shows on

| |

type |

shunt release |

closing electromagnet |

| parameter |

|

| voltage type |

AC |

DC |

AC |

DC |

| rated voltage(V) |

110 |

220 |

380 |

48 |

110 |

220 |

110 |

220 |

380 |

48 |

|

110 |

220 |

| rated current |

iron core start |

7 |

4 |

2.4 |

4.44 |

1.8 |

1.23 |

18 |

9.0 |

5 |

32 |

|

15.7 |

7.2 |

| iron core attract |

4.6 |

2.5 |

1.4 |

14 |

7.1 |

3.6 |

|

| rated power |

iron core start |

770 |

880 |

912 |

231.2 |

198.3 |

248.2 |

1980 |

1980 |

1900 |

1536 |

|

1727 |

1584 |

| iron core attract |

506 |

550 |

532 |

1540 |

1562 |

1368 |

|

| active voltage range |

65~120%rated voltage |

85~110%rated voltage |

|

4.5 CD type spring operation mechanism technique data shows on

| Item |

closing coil |

breaking coil |

| rated voltage(V) |

DC110 |

DC220 |

DC24 |

DC48 |

DC110 |

DC220 |

| active current(A) |

229 |

111 |

22.6 |

11.3 |

5 |

2.5 |

Note: brake shut current refers to calculated count, real current is less than the calculated count

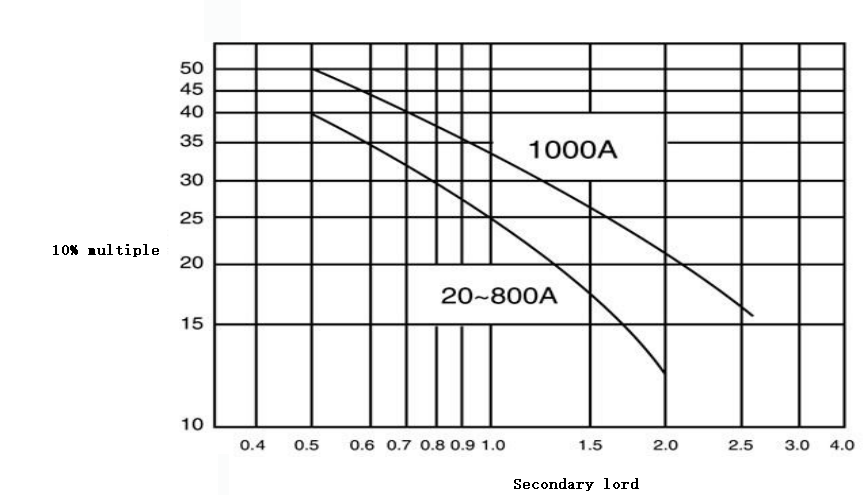

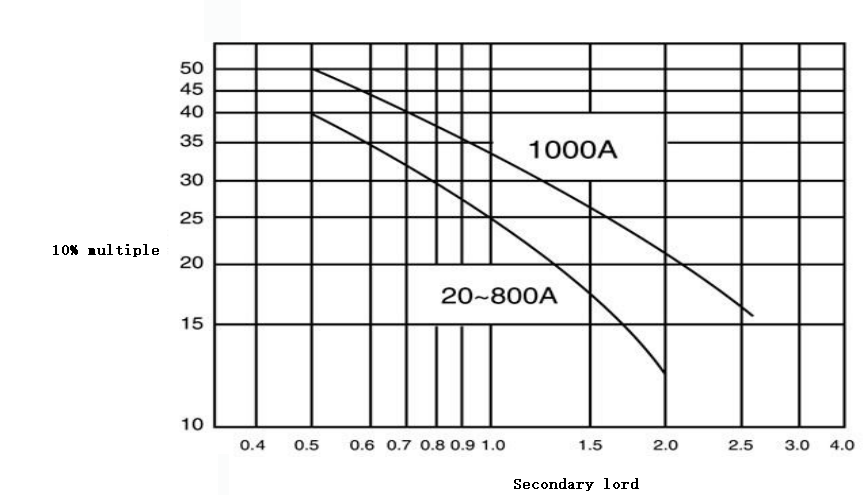

4.6 LCZ-35 current mutual inductor technique data shows on table 5,6 and diagram1

| Level combination |

rated primary current(A) |

rated secondary

current(A) |

class |

rated secondary

load(VA) |

|

10% multiple

no less than |

| |

| 0.5/3 |

0.5/0.5 |

20~100 |

5 |

0.5 |

50 |

|

|

| 0.5/B |

3/3. |

20~800 |

3 |

50 |

|

10 |

| 3/B |

B/B |

1000 |

B |

20 |

|

27 |

| B |

20 |

|

35 |

| rated primary curent(A) |

rated thermal stablecurrent(A) |

rated dynamic stable

current(A) |

rated primary current(A) |

rated thermal stable current (A) |

|

rated dynamic stable current(A) |

| |

| 20 |

1.3 |

4.2 |

200 |

13 |

|

42.2 |

| 30 |

2 |

6.4 |

300 |

19.5 |

|

63.6 |

| 40 |

2.6 |

8.5 |

400 |

26 |

|

84.9 |

| 50 |

3.3 |

10.6 |

600 |

39 |

|

127.3 |

| 75 |

4.9 |

16 |

800 |

52 |

|

112 |

| 100 |

6.5 |

21.2 |

1000 |

65 |

|

141.4 |

| 150 |

9.8 |

31.8 |

|

|

|

|

Diagram 1 LCZ-35 current mutual inductor grade B 10% multiple curve

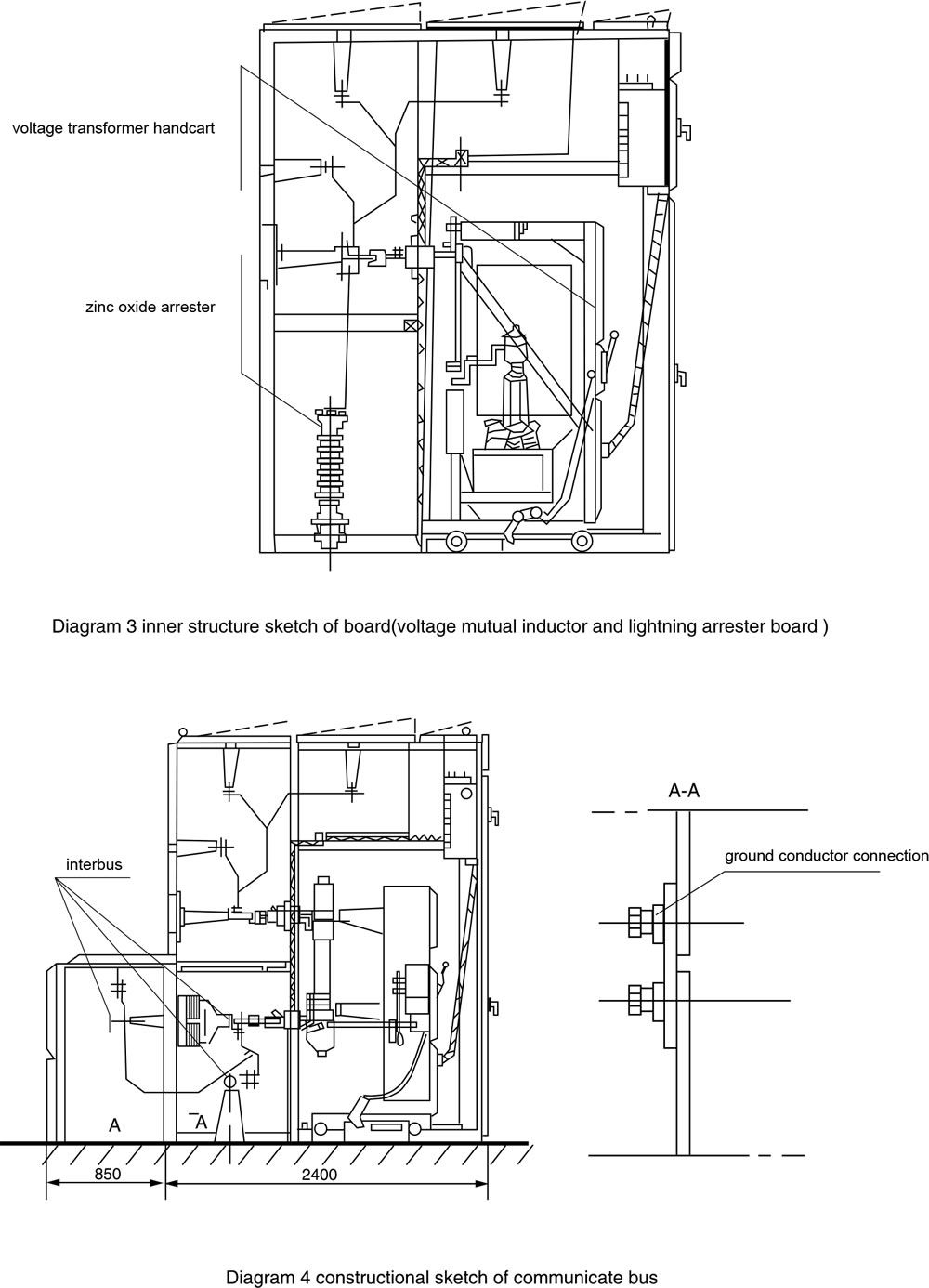

4.7 Voltage mutual inductor technique data

| Model No. |

rated voltage(V) |

rated capacity(VA) |

Max capacity(VA) |

primary coil

AX |

basic

AX

secondary

coil aX |

auxiliary

secondary

coil aDXD

rated capacity(VA)

0 |

0.5 class |

1 class |

3 class |

|

| JDJ2-35 |

35000 |

100 |

- |

150 |

250 |

500 |

1000 |

| JDJJ2-35 |

|

100/ .3 |

100/3 |

150 |

250 |

500 |

1000 |

4.8 FZ-35 type lightning arrester technique data

Rated voltage

(effective value)kV |

Arc-extinction

voltage (effective value)

kV |

power frequencydischarge voltage(effective value)kV |

impulse dischargevoltage pre-discharge time15~20ms(peak)kV |

residual voltage(10/20ms)peak kV |

| no less than |

no less than |

5kA |

10kA |

| 35 |

41 |

82 |

98 |

no more than 134 |

no more than 134 |

no more than 148 |

4.9 FYZ1-35 Zinc oxide lightning arrester technique data

Ratedvoltage(effective)

kV |

arrestershort-timeMax

operatevoltagekV

(effective) |

criticalpoint ofactionvoltage(lower limit)kv(peak) |

impulse voltageresidual voltage(wave form 8/20micro-seconds)(no more than)kV |

breaking and makingcapacity(no less than 20) |

residual voltage(10/20ms)peak kV |

| 2ms square waveno less than(A) |

18/40mS

impulse current(no less than)kA (peak value) |

impulseprotect

ratioU5kA |

operate

protect

ratioU300A |

| 35 |

41 |

59 |

126 |

300 |

10 |

2.1 |

1.8 |

4.10 RN 2 type high voltage rated current fuse technique data

rated voltage

kv |

rated current

kV |

phase-loss capacity

(3-phase)MVA

MVA |

Max breaking

current

kA |

Max current(peak)

of ultimate short

-circuit current

breaking(A) |

|

fuse resistance |

| |

| 35 |

0.5 |

1000 |

17 |

700 |

|

315 |

4.11 Rw10-35/3 type limited current fuse technique data

| model No. |

rated voltage kV |

rated current kA |

phase-loss capacity

(3-phase)MVA |

|

Max breaking current kA |

| |

| RW10-35/3 |

35 |

3 |

1000 |

|

16.5 |

4.12 Sj-5/0.4/0.23 type distribution transformer technique data

| rated capacity kVA |

rated voltage kV |

rated current A |

loss A |

| hign-voltage |

low-voltage |

hign-voltage |

low-voltage |

hign-voltage |

|

low-voltage |

| 50 |

35 |

0.4 |

0.825 |

72.2 |

490 |

|

1325 |

| resistance voltage % |

without load current % |

connection group |

weight kg |

| total |

|

oil weight |

| 6.5 |

9 |

Y/Y0-12 |

880 |

|

340 |

4.13 ZN23-35 inner high voitage vacuum breaker main technique parameter

| code |

Item |

Unit |

data |

| 1 |

rated voltage |

KV |

35 |

| 2 |

Max operate voltage |

KV |

40.5 |

| 3 |

rated insulation level |

KV |

power frequency 95 one min;thunder impulse(peak) 185 |

| 4 |

rated current

kV |

A |

1600 |

| 5 |

rated short-circuit breaking current |

KA |

25/31.5 |

| 6 |

rated breaking current break number of times |

time |

20 |

| 7 |

rated short-circuit closing current(peak) |

KA |

63/80 |

| 8 |

rated short-circuit continuous time |

S |

4 |

| 9 |

rated operate sequence |

|

break -0.3 – cose and break 180s – close and break |

| 10 |

closing time |

S |

≤0.2 |

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

ProductWe will always adhere to the "mutual benefit and win-win" concept of cooperation, customer demand oriented,customer satisfaction as the goal, to provide customers with reliable products and super expected service.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE

SolutionsProducts are widely used in power, communication, chemical, mining, metallurgy, transportation, petroleum, railway and other important fields.MORE ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE

ServiceWe will continue to take quality management as the core, high-tech as the guidance, with customers at home and abroad to establish strategic partnership, win-win cooperation, create a better future!MORE About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE

About UsPeople Electrical Appliance Group is one of China top 500 enterprise and Global Top 500 machinery company.MORE