To constantly improve the management system by virtue of the rule of “sincerely, good faith and quality are the base of enterprise development”, we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for China Manufacturer for FC100e AC Drive Vector Control Frequency Inverter 220V/380V Input, We have expanded our business into Germany, Turkey, Canada, U. S. A. , Indonesia, India, Nigeria, Brazil and some other regions of the world. We are working hard to be one of the best global suppliers.

To constantly improve the management system by virtue of the rule of “sincerely, good faith and quality are the base of enterprise development”, we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for AC Drive and Delta AC Drive, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We are going to not live up to the historic opportunity of the times.

The frequency converter is mainly composed of rectifier (AC to DC), filter, inverter (DC to AC), braking unit, driving unit, detection unit, micro processing unit, etc. The inverter adjusts the voltage and frequency of the output power supply by breaking the internal IGBT, and provides the required power supply voltage according to the actual needs of the motor to achieve the purpose of energy saving and speed regulation. In addition, the inverter has many protection functions, such as overcurrent, overvoltage, overload protection, etc.

1. Frequency conversion energy saving

2. Power factor compensation energy saving – due to the role of the internal filter capacitor of the inverter, the reactive power loss is reduced and the active power of the grid is increased

3. Soft start energy saving – using the soft start function of the frequency converter will make the starting current start from zero, and the maximum value will not exceed the rated current, reducing the impact on the power grid and the requirements for power supply capacity, and extending the service life of equipment and valves. The maintenance cost of the equipment is saved.

2.1 Humidity: Relative humidity shall not excced 50% at the Max temperature 40°C, and higher humidity could be accepted at lower temperature. The condensation must be taken care which is caused by temperature change.

When temperature is above +40°C, loaction should be well-ventilated. When environment is unstandard, please using telecontrol or electrical cabinet. Inverter working life is affected by install location. Longtime continuous using, the life electrolytic capacitor in inverter would not exceed 5 years, cooling fan life would not exceed 3 years, exchange and maintenance should be done earlier.

To constantly improve the management system by virtue of the rule of “sincerely, good faith and quality are the base of enterprise development”, we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for China Manufacturer for FC100e AC Drive Vector Control Frequency Inverter 220V/380V Input, We have expanded our business into Germany, Turkey, Canada, U. S. A. , Indonesia, India, Nigeria, Brazil and some other regions of the world. We are working hard to be one of the best global suppliers.

China Manufacturer for AC Drive and Delta AC Drive, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We are going to not live up to the historic opportunity of the times.

Specification

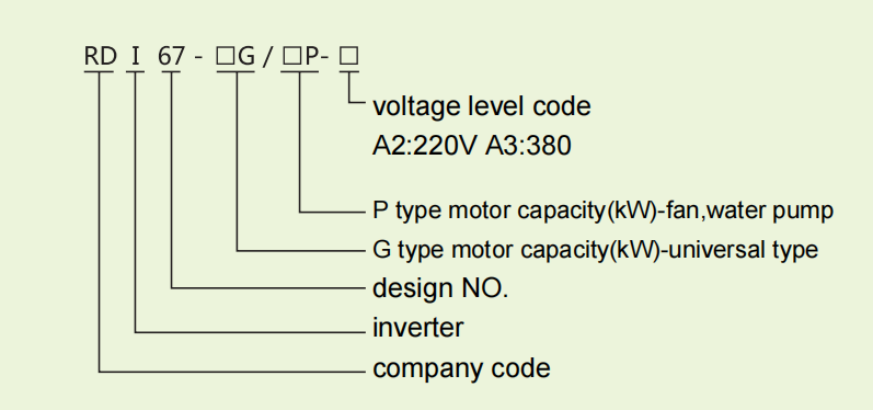

Voltage type: 380V and 220V

Applicative Motor capacity: 0.75kW to 315kW

Specification see Table1

| Voltage | Model No. | Rated capacity (kVA) | Rated output current (A) | Applicative motor (kW) |

| 380V three-phase |

RDI67-0.75G-A3 | 1.5 | 2.3 | 0.75 |

| RDI67-1.5G-A3 | 3.7 | 3.7 | 1.5 | |

| RDI67-2.2G-A3 | 4.7 | 5.0 | 2.2 | |

| RDI67-4G-A3 | 6.1 | 8.5 | 4.0 | |

| RDI67-5.5G/7.5P-A3 | 11 | 13 | 5.5 | |

| RDI67-7.5G/11P-A3 | 14 | 17 | 7.5 | |

| RDI67-11G/15P-A3 | 21 | 25 | 11 | |

| RDI67-15G/18.5P-A3 | 26 | 33 | 15 | |

| RDI67-18.5G/22P-A3 | 31 | 39 | 18.5 | |

| RDI67-22G/30P-A3 | 37 | 45 | 22 | |

| RDI67-30G/37P-A3 | 50 | 60 | 30 | |

| RDI67-37G/45P-A3 | 61 | 75 | 37 | |

| RDI67-45G/55P-A3 | 73 | 90 | 45 | |

| RDI67-55G/75P-A3 | 98 | 110 | 55 | |

| RDI67-75G/90P-A3 | 130 | 150 | 75 | |

| RDI67-93G/110P-A3 | 170 | 176 | 90 | |

| RDI67-110G/132P-A3 | 138 | 210 | 110 | |

| RDI67-132G/160P-A3 | 167 | 250 | 132 | |

| RDI67-160G/185P-A3 | 230 | 310 | 160 | |

| RDI67-200G/220P-A3 | 250 | 380 | 200 | |

| RDI67-220G-A3 | 258 | 415 | 220 | |

| RDI67-250G-A3 | 340 | 475 | 245 | |

| RDI67-280G-A3 | 450 | 510 | 280 | |

| RDI67-315G-A3 | 460 | 605 | 315 | |

| 220V single-phase |

RDI67-0.75G-A3 | 1.4 | 4.0 | 0.75 |

| RDI67-1.5G-A3 | 2.6 | 7.0 | 1.2 | |

| RDI67-2.2G-A3 | 3.8 | 10.0 | 2.2 |

Single phase 220V series

| Applicative motor (kW) | Model No. | Diagram | Dimension: (mm) | |||||

| 220 series | A | B | C | G | H | intall bolt | ||

| 0.75~2.2 | 0.75 kW~2.2kW | Fig2 | 125 | 171 | 165 | 112 | 160 | M4 |

Three phases380V series

| Applicative motor (kW) | Model No. | Diagram | Dimension: (mm) | |||||

| 220 series | A | B | C | G | H | intall bolt | ||

| 0.75~2.2 | 0.75kW~2.2kW | Fig2 | 125 | 171 | 165 | 112 | 160 | M4 |

| 4 | 4kW | 150 | 220 | 175 | 138 | 208 | M5 | |

| 5.5~7.5 | 5.5kW~7.5kW | 217 | 300 | 215 | 205 | 288 | M6 | |

| 11 | 11kW | Fig3 | 230 | 370 | 215 | 140 | 360 | M8 |

| 15~22 | 15kW~22kW | 255 | 440 | 240 | 200 | 420 | M10 | |

| 30~37 | 30kW~37kW | 315 | 570 | 260 | 230 | 550 | ||

| 45~55 | 45kW~55kW | 320 | 580 | 310 | 240 | 555 | ||

| 75~93 | 75kW~93kW | 430 | 685 | 365 | 260 | 655 | ||

| 110~132 | 110kW~132kW | 490 | 810 | 360 | 325 | 785 | ||

| 160~200 | 160kW~200kW | 600 | 900 | 355 | 435 | 870 | ||

| 220 | 200kW~250kW | Fig4 | 710 | 1700 | 410 | Landing cabinet installation | ||

| 250 | ||||||||

| 280 | 280kW~400kW | 800 | 1900 | 420 | ||||

| 315 | ||||||||

Appearance and mounting dimension

Shape size see Fig2, Fig3, Fig4, operation case shape see Fig1